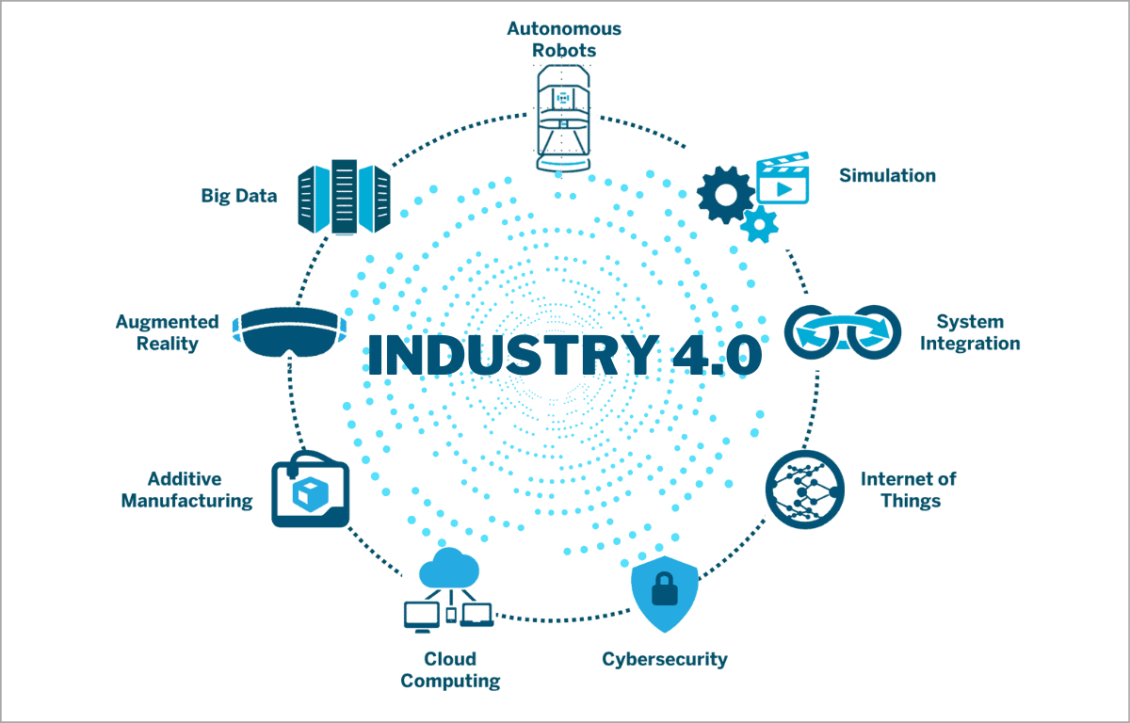

Industry 4.0, also known as the fourth industrial revolution, refers to the way advanced manufacturing technology, automation, cloud computing, analytics, AL, and ML are changing and improving product distribution to consumers. The adoption of new technologies and processes allows for more efficient and cost-effective supply chain and logistics management.

Industry 4.0 builds on the innovations made possible by the third industrial revolution (digital revolution) which took place from the 1950s to the early 2000s and gave rise to the internet, computer, and other electronic development. Four types of fundamental technologies can be used to increase the scope of an invention’s potential.

- Computational power: E.g. blockchain, cloud technology, etc.

- Analytics and intelligence: E.g. artificial intelligence, machine learning.

- Human-machine interaction: E.g. virtual reality (VR), augmented reality (AR), robotics and automation, etc.

- Advance engineering: E.g. additive manufacturing, renewable energy, nanoparticles, etc.

One of the key factors of Industry 4.0 in the global supply chain and logistics industry is the use of automation and robotics. The use of UAVs, drones, robots, etc has improved the speed and efficiency of the supply chain and reduced factory waste. For last-moment deliveries, drones and UAVs are also being used which cuts down on cost and delivery times.

Robotics and automation has also improved safety in the supply chain industry by reducing the risk of injuries from manual tasks such as heavy lifting and repetitive motions. This has led to a reduction in workplace injuries and reduced the cost of insurance and compensation.

With robotics and automation, the growing usage of big data and analytics also has a significant impact. By allowing businesses to gather, analyze and act on massive amounts of data, advanced analytics technologies increased the agility and visibility of the supply chain. As a result, businesses may better estimate demand, manage inventory, and improve their operations. Real-time tracking is also made possible by cargo IoT sensors and RFID technology (radio frequency identification) allowing businesses to spot problems as soon as possible and act on them. Data analytics is being used to identify and mitigate the risks in the supply chain. This includes identifying potential disruptions in the supply chain such as natural disasters or geopolitical events, and developing contingency plans to mitigate the impact.

As e-commerce has grown, there is a greater need for logistics services as businesses look for creative methods to enhance the client experience. Customers can now take advantage of faster and more flexible delivery choices thanks to the development of new logistics models like crowd shipping and collaborative logistics.

In conclusion, the impact of Industry 4.0 on the global supply chain and logistics industry has been transformative. Automation, robots, and data analytics have all been successfully integrated to boost efficiency, accuracy, and safety while lowering costs. Businesses and companies are now able to optimize their supply chains, improve visibility, and respond quickly to disruptions. Businesses that utilize these technological advancements and modernize will be successful. Industry 4.0 is definitely the future of the supply chain and logistics sector.