Artificial Growth of algae & subsequent drain of nitrogen based chemicals.

- While searching for technical solution, one has to keep in mind that technology should not induce other problems while solving one problem.

- Also when we say water management it’s not controlling our limit of use but to artificially induce natural recycle process by studying nature. The best way to tackle waste is to match it with waste utilization. Manipulation of waste is like shifting it from one system to another without actually reducing the same.

- Here I will be talking on a method that study natural water recycling method and adoption of the same instead of chemical processes which solve one problem and create another.

Eutrophication:-

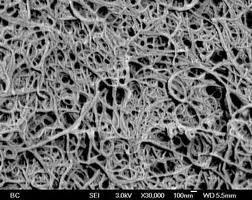

- Eutrophication can be human-caused or natural. Untreated sewage effluent and agricultural run-off carrying fertilizers are examples of human-caused eutrophication. However, it also occurs naturally in situations where nutrients accumulate (e.g. depositional environments), or where they flow into systems on an ephemeral basis. Eutrophication generally promotes excessive plant growth and decay, favoring simple algae and plankton over other more complicated plants, and causes a severe reduction in water quality. Phosphorus is a necessary nutrient for plants to live, and is the limiting factor for plant growth in many freshwater ecosystems. The addition of phosphorus increases algal growth, but not all phosphates actually feed algae. These algae assimilate the other necessary nutrients needed for plants and animals. When algae die they sink to the bottom where they are decomposed and the nutrients contained in organic matter are converted into inorganic form by bacteria. The decomposition process uses oxygen and deprives the deeper waters of oxygen which can kill fish and other organisms. Also the necessary nutrients are all at the bottom of the aquatic ecosystem and if they are not brought up closer to the surface, where there is more available light allowing for photosynthesis for aquatic plants, a serious strain is placed on algae populations. Enhanced growth of aquatic vegetation or phytoplankton and algal blooms disrupts normal functioning of the ecosystem, causing a variety of problems such as a lack of oxygen needed for fish and shellfish to survive. The water becomes cloudy, typically colored a shade of green, yellow, brown, or red.

- Naturally Algal blooms occur when excess of plant nutrient (Nitrates & Phosphates) is available in the water-A natural cleansing process.

- These blooms have been found to destroy fishes in fresh water because of the low oxygen level initiated by planktons feeding on algae after death at the lower water level.

- It has been found that the root cause of imbalance in water is excess of nitrates & phosphates. So the target should be root cause.

- Thus we could encourage algal growth for nitrate reduction outside the fresh water body & thereby decrease the nitrate & phosphate level and also increase food for planktons /phosphorous fixating bacterias/nitrogen fixating bacterias-which are then eaten by marine life-A natural phenomenon initiated artificially.

- The excess of algae may be used as a bio-diesel or may be fed by phytoplankton to zooplanktons to small fishes to large fishes & the eco-logic continues.

- Well traditionally ion exchange methods used in industries are used for nitrate reduction however nitrates do not go away from system they are just removed from water source & they appear in other system.eg:-

In ion-exchange resins the nitrate ion is removed from water source by exchanging with chloride ions. After the exchange the nitrates present in the resin bed are exchanged with HCL to regenerate resin producing HNO3 .thus we see that still overall system –the eco-system has nitrates still left & will somehow or other reappear. Also the chlorides that we exchanged are also as dangerous as nitrates if present in large quantity. So any chemical process is a curtain to existing problem it no longer solves problem as a whole. A bio-chemical process is therefore best by observing nature.

- Also biological dentrification is used in which nitrates are converted to Nitrogen gas.

- The process is similar to denitrification done by anaerobic bacterias but those require organic food in plenty to convert nitrates ultimately each natural process comes down to bacteria and microbes level as they are natural scavengers but those attract pests and rodents bad odor etc.

Disadvantage:-

- The time algal growth requires, the time planktons & other organism requires to complete a food-web is high .hence this system may be only used in areas where there is no continuous addition of nitrates-small industries letting off waste in 5 days, a farming site where agricultural run-off carries phosphates & nitrates during rainy season, a waste water treatment plant having large base for each pond for cultivation.

Use of reflectors as flyers controlled by the control station to reflect the amount of power in a cellular structure:-

- In a cellular structure the transmitting & receiver (duplex antenna) is one that radiates micro-waves for mobile communication. Generally in urban areas where concentration of mobile phones is very high the towers are placed on residential towers or offices or shops etc.

- There is a growing debate on whether the electromagnetic exposure can cause tumors or cancer. Although few researchers have shown the opposite but practically over exposure to micro-waves can definitely lead to a disorder because these waves tend to heat the body temperature when they pass through our body. The tissues break in to cells creating disorder in the body due to high temperature.

- Even though limits of radiation are standardized by government ,continuous exposure is dangerous for all of us. people living near towers face high dangers of exposure while people far away likely do not .since power density of the antenna is high near the antenna & starts reducing as the distance increases.

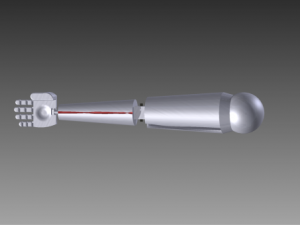

- So we can direct a high powered beam of radiations towards a secondary tower flying in the sky over a cellular structure at heights calculated for power required & that can be used as a transmitter receiver to be communicated with the base station.

- This will always ensure uniform power spread & the affect of heat effect of micro-waves would be reduced.

- This will ensure constant power density on surface of earth (exceptions hills, mountains etc.) to be used for purpose of communication rather than concentrated power density.

Disadvantages:-

- Mobile base station makers will have to share extra costs for making new equipment controllable from control tower as well.

- Finding out space in the sky for installing each such station over which we can place the flying station which will not be interfered by birds, airplanes, ionosphere reflection, etc.

Possibility/Feasibility:-

A free wireless internet service for developing economies called “Project Loon” was announced by Google & initially was surveyed in New-Zealand by a farmer for wireless internet by sending balloons carrying transponders receptors & efficient mechanism for looming around a particular region just like a geo-synchronous satellite. This will also be in India, South-Africa.

An ICT model for empowering rural population:-

Our government spends 60000 crore in Nrega-a scheme which is aimed at providing opportunities for employment in 100 days. A worker from rural area is made to toil for breaking stones & he gets his income from that. With bundles of corruption, this scheme neither utilizes individual potential of a farmer, a child, a painter, a porter goldsmith etc. to meet their expenses rural public do .Instead of this each village can have a “centre of internet” where everything that an urban Indian gets rural India also has.

- Healthcare:

Supply of generic medicines as when needed, supply essential supplements for maternal ,child health through a WLAN connections each in one village, asking possible diagnostic questions to doctors who are unwilling to go to rural side, people will tell their day to day activities & doctors would suggest diseases that can occur or a database of diseases in different languages.

- Entrepreneurship:

Popularity of village & direct details of those involved in sale of those materials online.

- Current trends of market:

Current Wheat, Rice, Moong, etc. to give farmers a fare share of their products

Giving their new inventions on web may be integrated with National Innovation Foundation (NIF).

- Education.